I took a long nap after work today. And there was a seabreeze so I thought the surf would be choppy.

After I got up but before I started cooking dinner, I went into the garage and got the window holes cut into Marvin's two prone foil boards. I didn't take pictures of those, but I did it.

Then I sanded the laps on No.36 in preparation for laminating the top deck.

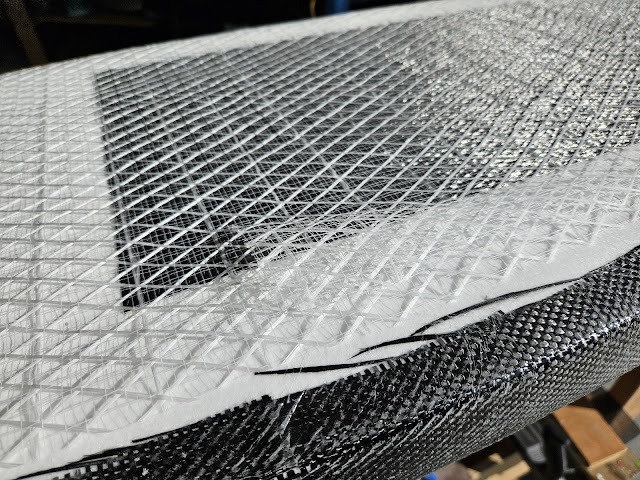

Here it is all sanded.

Then I wiped all the nonporous surfaces with alcohol to clear any dust and oils (MARLON).

I didn't take a picture of the underlayment (scrap carbon fiber pieces and a patch of innegra) - but I spent some time getting that arranged and laid out.

Then I got the cover sheet trimmed and the laps cut in.

I cut slots in all the layers where the footstrap inserts are - primarily to help the layers lay flatter and to give any trapped air a route to escape.

I used 15.4 ounces on the first pour (mainly focused on the underlayment/patch). Then I mixed another 5.6 ounces to get the laps wetted out.

I went over the thicker areas to make sure nothing was floating. I think doing the underlayment separately helps to keep the lamination from floating (too much epoxy) or from being to dry.

I used the extra epoxy to make a small batch of glass bubbles slurry which I poured into the top deck window holes on the two prone boards. I may have had an ounce left over (nice!).

So far this lamination job came out really nice. I got surprised on the bottom deck with some sneaky air bubbles on the rail. For the top deck I stayed with the board while the epoxy was hardening. I even placed saran wrap to get some of the stray fibers to stay down and used that opportunity to make sure the rest of the lamination was sitting tight.

If everything turns out ok, the hard part is done. With the seabreezes expected in the afternoons this week, I should actually get a lot of progress done - two fill coats on each side, sanding-sanding-sanding, vent and leash plug installations, and more sanding.

I'm contemplating painting tiger stripes on the bottom deck...

Tomorrow I'll sand the laps and get a layer of epoxy on to where the logos will go to get a smooth surface established. If you've read this far you have seen this before - this is the home stretch!