I decided to truly take a break from surfing/foiling today - so I used the time to get these two prone boards advanced.

First I routed out the slots for the reinforcement blocks. Then I cleaned up the edges so the blocks would fit in snug (not too tight - need room for the fabric).

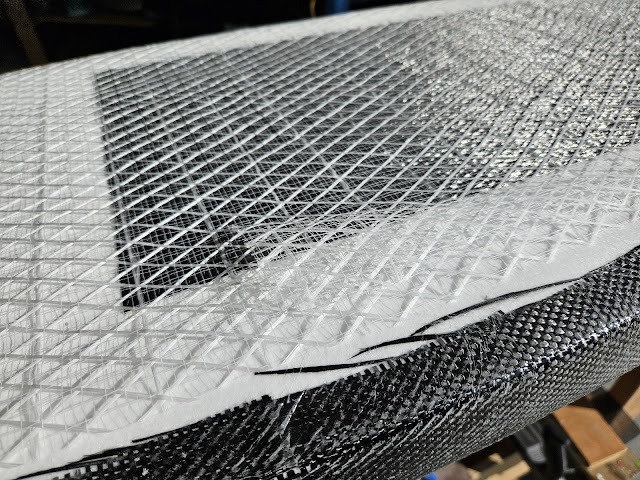

These first pictures are the carbon layers added in. I use offcuts from the bottom laminate from previous boards (this stuff is not cheap - I try and use all of it).

On these boards, I did something different than previous builds. I broke up what would normally be a combined step into two separate ones. In the single step version of getting the fabrics wetted out and then placing the reinforcement block immediately after, the top fabric usually pulls. Even though this part of the board is never seen in the finished product, I still wanted to do it so the fabric doesn't pull.

This first of two separate steps was to wet out only the top part of the fabric that would stay above the routed out hole. I placed saran wrap over the fabric, placed the blocks in place to hold the fabric in place and added soft weights to help keep the fabric down.

The next step was to add some more fabric to the bottom - this is scrap innegra (even more expensive than carbon fiber), then I wetted out the bottom and sides of the hole, added a layer of epoxy thickened with Thiksil, and then placed the block in.

I filled the gap with some straight epoxy (flows into the gaps easier), then covered the blocks with saran wrap and placed the weights on the outer edges of the blocks.

The next step on these will be to rout out the finbox slots in these blocks. Then I'll flip the boards and rout out a thin layer of foam on the top deck where my left heel goes - I'll press on a thin sheet of divynicell.

From there I'll laminate on the top deck fabric, then flip the board and epoxy in the finboxes and laminate the bottom deck.

There's more (a lot more), but these prone boards get done faster than the wing boards.