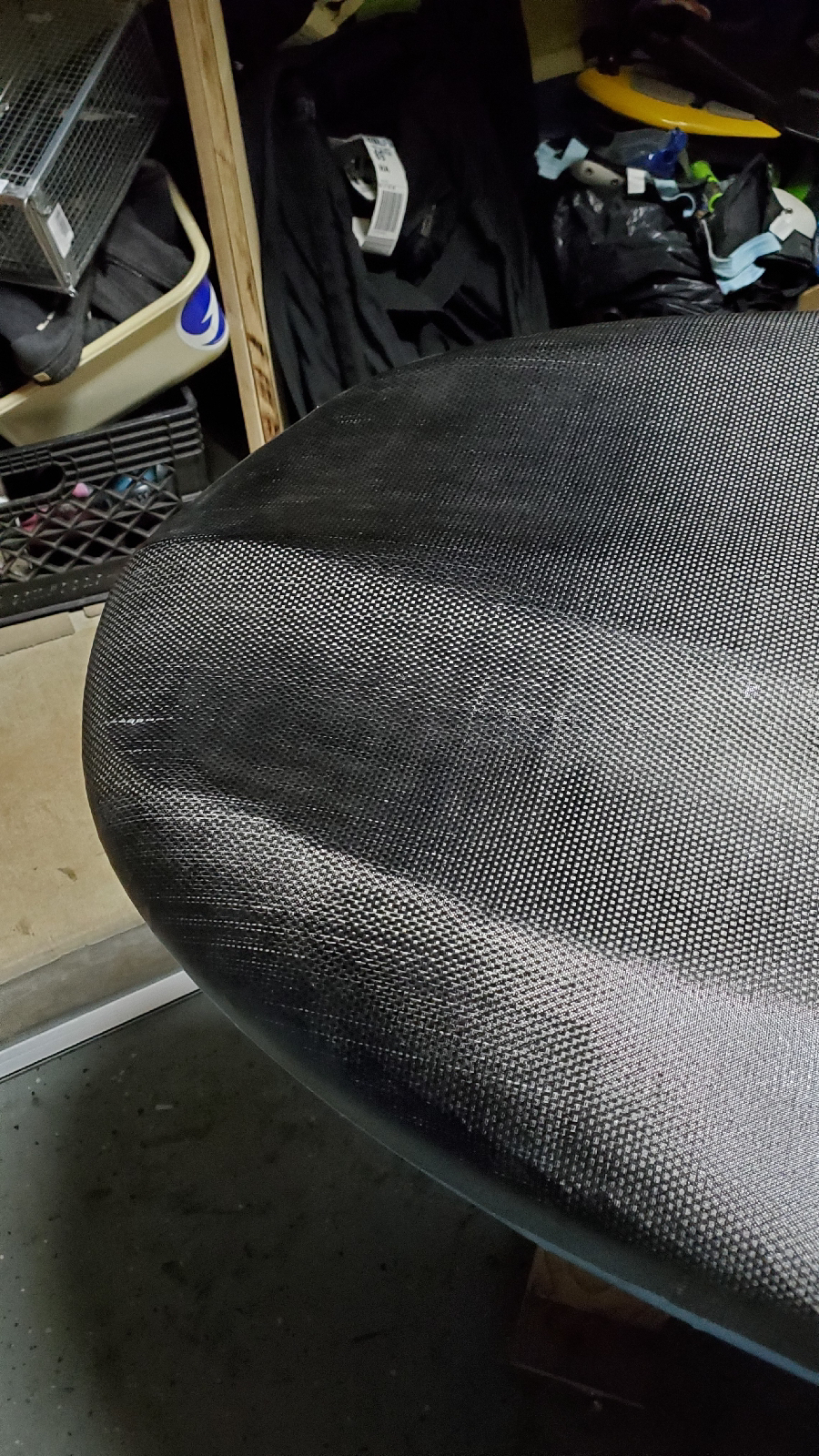

I passed on the evening session today - the tide was too low anyways, but I really wanted to get through this part of the process on Kalani's board. Under this layer of 2 ounce fiberglass is a nose to tail layer of 4.8 ounce carbon fiber, and another layer of carbon acting as a stringer connecting the boxes to the bottom deck.

I always sweat this part - during summer the slow hardener isn't really that slow. And the alignment always seems to get misaligned after getting the boxes epoxied in.

This one came out really nice. I spent a lot of time cutting the laps to try and minimize overlapping in an attempt to reduce sanding. I'm still going to have to grind and fill and sand - but hopefully that will go quick.

The nose half of the board has only one layer of innegra (on top) and carbon fiber (bottom, but with a cover sheet of 2 ounce fiberglass). That was specifically done to reduce the weight up front, as well as the overall weight - but without sacrificing strength where it is needed. Kalani really rides his gear hard - this is as much as experiment for me as it is a new board for him. If this board survives him, I know I've gotten to an optimized layup.

There is still a bunch of work left - adding carbon tape to the rail all around to hide the carbon lap, adding to logos, fill coat, grind the boxes open, drill out the plug holes, epoxy in the plugs, fill any voids, sand everything down, and sign the board. All that, but the hard part is pretty much done.

No comments:

Post a Comment